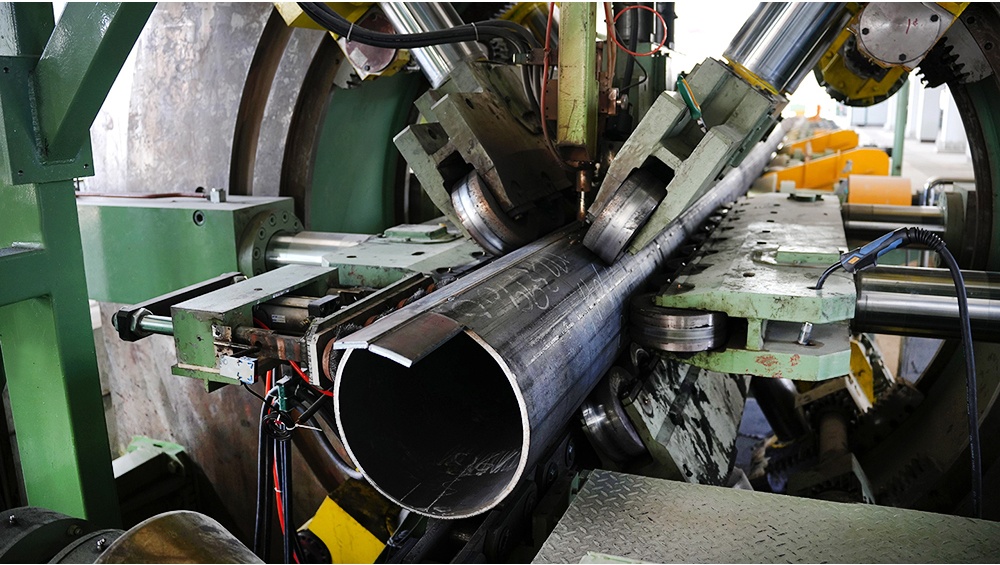

At present, pipelines are mainly used in long-distance oil and gas transportation, and the pipe steel pipes used in long-distance pipelines are mainly spiral submerged arc welded steel pipes and straight seam double-sided submerged arc welded steel pipes. Because the spiral submerged arc welded pipe is made of strip steel, the wall thickness is limited, and the improvement of steel grade is limited by the heat treatment of the material. In addition, the spiral submerged arc welding pipe has some insurmountable shortcomings, such as long weld, large residual stress, and poor reliability of the weld.

With the increasing demand for oil and gas conveying steel pipes, they are no longer used in densely populated areas and areas with high reliability requirements, and spiral welded pipes are gradually being replaced by straight seam welded pipes.

with the development of oil exploitation to the depths of the ocean, due to the combination of pressure, impact force and bending force, the transmission pipeline laid on the seabed is also flattened, which is the weak link of the spiral welded pipe. In order to improve the conveying capacity of the pipeline and ensure the development of the submarine pipeline to the direction of thick wall, the submarine pipeline mostly uses straight seam welded pipe. Therefore, compared with spiral welded pipe, straight seam welded pipe has higher dimensional accuracy and easier repair welding, so from this aspect, straight seam welded pipe is also preferred.

coal slurry slurry and slurry pipeline need to use straight seam welded pipe, pipeline transportation is "paste" pipeline transportation is up the direction. Because the seam residual height of spiral welded pipe is helical, the resistance to coal slurry is large, and the pipe needs larger wall thickness, so the straight seam welded pipe is inclined to be used.

machinery, construction, chemical and other industries need straight seam welded pipe. At present, the mechanical industry uses forgings to manufacture the valve seat after processing the inner hole, labor, time and material consumption, if the thick wall straight seam welded pipe is used, it will be a lot of economy. In addition, due to the mechanical properties of anti-flattening, only straight seam welded pipe is used for construction. Chemical pipe also want to use straight seam welded pipe.

The company's products are mainly used in oil, natural gas, water, steam, gas and other high, medium and low pressure fluid transportation pipelines and structural steel pipes, and undertook the construction of landmark projects at home and abroad, the products are sold to various cities and exported to Southeast Asia, the Middle East, Europe and the United States and other more than 80 regions.