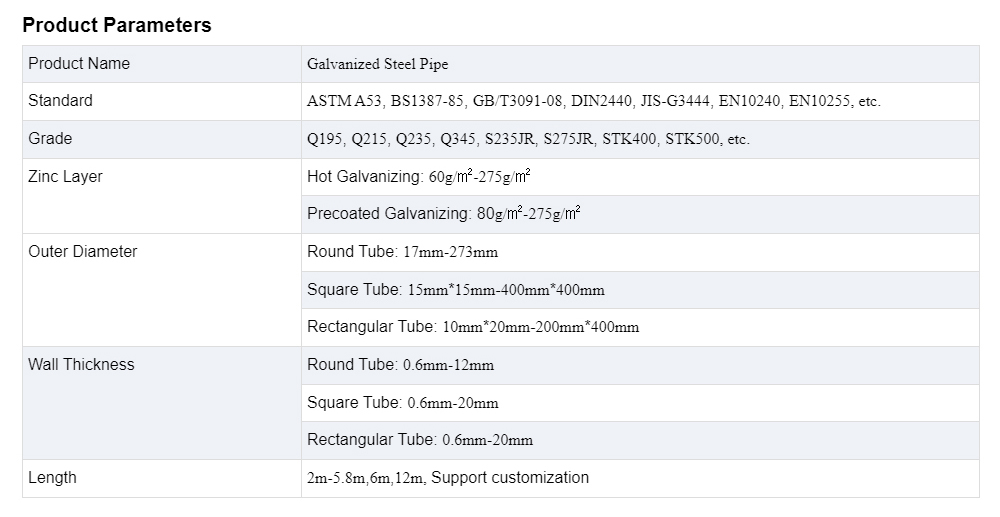

ASTM A53 schedule 40 hot dipped galvanized steel pipe

- China

- 15-25 Working Days

- Factory Direct Supply

ASTM A53 schedule 40 hot dipped galvanized steel pipe

galvanized pipe is the reaction of molten metal with iron matrix to produce an alloy layer, so that the matrix and the coating are combined. Hot dip galvanizing has the advantages of uniform coating, strong adhesion and long service life. Complex physical and chemical reactions occur between the steel tube substrate and the molten bath to form a tight zinc-iron alloy layer with corrosion resistance. The alloy layer is integrated with the pure zinc layer and the steel pipe matrix. Therefore, its corrosion resistance is strong.

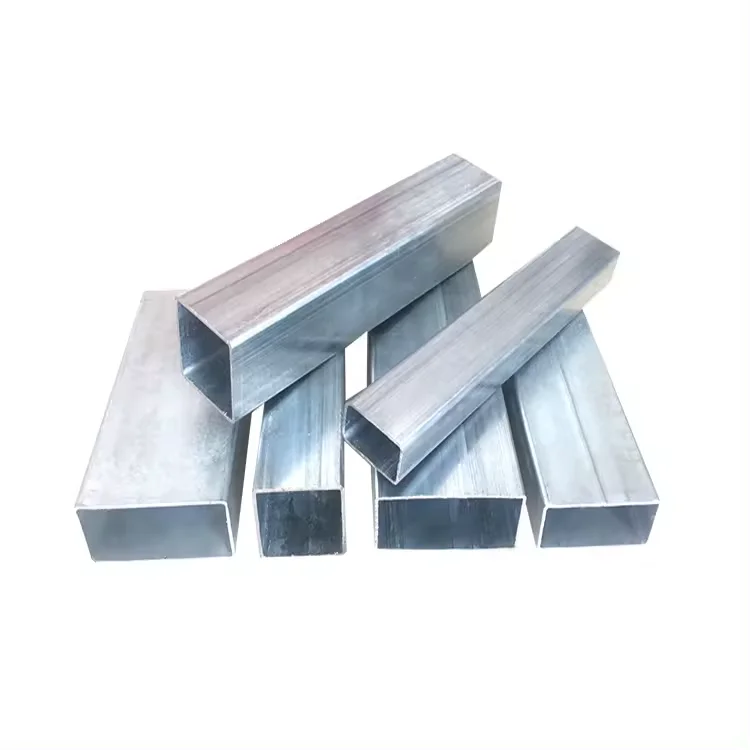

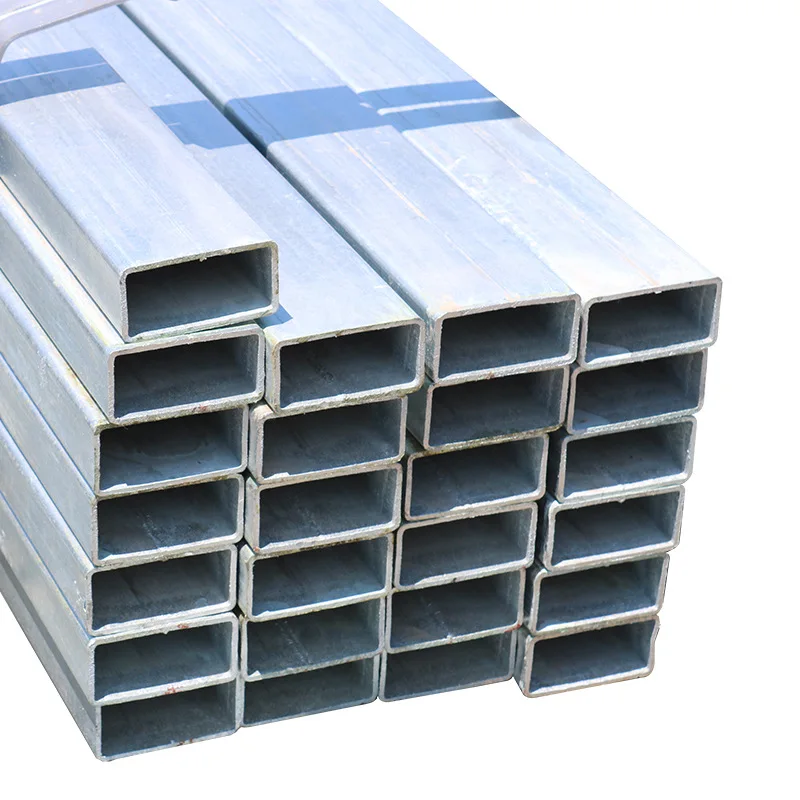

Galvanized Steel Pipe Description

Galvanized pipe is a metal pipe whose surface is covered with a layer of zinc, which has good anti-corrosion properties and durability. Hot-dip galvanized pipe is a steel pipe that is heated at high temperature and then immersed in a galvanizing solution to form a thick zinc layer, which has high anti-corrosion performance and durability. Electroplated galvanized pipe uses steel pipe as the cathode and deposits a thin zinc layer on the surface through electrolysis, which has good anti-corrosion performance and decorative properties. Galvanized pipes are widely used in water supply, drainage, heating and other piping systems in the construction field and are widely used in sewage, rainwater, tap water and other pipeline systems in the municipal field.

Scope of Application

After galvanizing, these metal pipes can be used for many different purposes, such as: water pipes, gas pipes, chemical pipes, sanitary pipes, HVAC pipes and industrial pipes. They are often used in building construction and the development of water supply systems because they are very durable and last longer than other types of pipes such as PVC (polyvinyl chloride) or copper pipes.

Participate In Exhibition

Participate In Exhibition