EN8/EN9 En Series Round Steel Bar

EN8/EN9 En Series Round Steel Bar Description

The chemical composition of EN8 includes carbon (C), silicon (Si), manganese (Mn), phosphorus (P), sulfur (S) and other elements. The carbon content is the most important, usually between 0.36-0.44%. EN8 has good weldability, and it can be welded by conventional welding methods, such as arc welding, gas welding, etc. However, when performing high-intensity welding, care needs to be taken to control the welding heat to prevent material deterioration. EN8 carbon steel bars are widely used in the manufacturing industry, especially where high strength and wear resistance are required. They are often used to manufacture bearings, pins, mechanical parts, etc..

Product Parameters

Product Name | EN8/EN9 En Series Round Steel Bar | |||

Standard | EN/DIN/JIS/ASTM/BS/ASME/AISI, etc. | |||

Common Round Bar Specifications | 3.0-50.8 mm, Over 50.8-300mm | |||

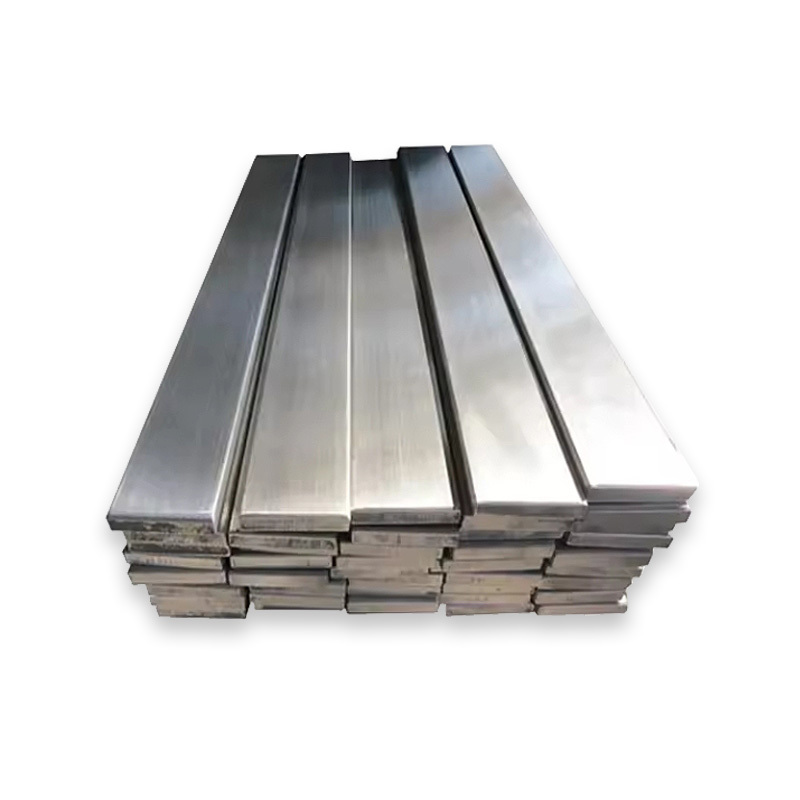

Flat Steel Common Specifications | 6.35x12.7mm, 6.35x25.4mm, 12.7x25.4mm | |||

Hexagon Bar Common Specifications | AF5.8mm-17mm | |||

Square Bar Common Specifications | AF2mm-14mm, AF6.35mm, 9.5mm, 12.7mm, 15.98mm, 19.0mm, 25.4mm | |||

Length | 1-6meters, Size Accept Custom | |||

Diameter(mm) | Hot Rolling Round Bar | 25-600 | Cold Rolling Square Bar | 6-50.8 |

Hot Rolling Square Bar | 21-54 | Cold Rolling Hexagon Bar | 9.5-65 | |

Cold Rolling Round bar | 6-101.6 | Forged Rebar | 200-1000 | |

Surface Process | Bright, Polished, Black | |||

Other Services | Machining(cnc), Centerless Grinding(cg), Heat Treatment, Annealing, Pickling, Polishing, Rolling, Forging, Cutting, Bending, Small Machining, etc. | |||

Chemical Composition

Grade | C % | Si % | Mn % | Cr % | Mo % | W % |

EN-1A | 0.007-0.15 | 0.10 | 0.80-1.00 | S | P | - |

0.20-0.30 | 0.70 MAX | |||||

EN-8 | 0.35-0.45 | 0.05-0.30 | 0.60-1.00 | S | P | - |

0.06 MAX | 0.06 MAX | |||||

EN-9 | 0.50-0.60 | 0.05-0.30 | 0.5-0.80 | - | - | - |

EN-19 (V 320) | 0.35-0.45 | 0.10-0.30 | 0.5-0.80 | 0.90-1.40 | 0.20-0.40 |

|

EN-24 (V 130) | 0.35-0.45 | 0.10-0.35 | 0.45-0.70 | 0.90-1.40 | 0.20-0.35 | NI |

1.3-1.8 | ||||||

EN-31 R-100 | 0.90-1.20 | 0.10-0.35 | 0.30-0.75 | 1.00-1.60 | - | - |

EN-36C E-200 | 0.12-0.18 | 0.10-0.35 | 0.30-0.60 | 0.60-1.10 | - | NI |

3.0-3.75 | ||||||

EN-42 | 0.70-0.85 | 0.10-0.40 | 0.55-0.75 | - | - | - |

EN-44 | 0.90-1.20 | 0.30 | 0.45-0.70 | - | - | - |

EN-45 F-110 | 50-0.60 | 1.5-2.0 | 0.70-1.00 | - | - | - |

EN-351 | 0.10-0.20 | 0.35 | 0.60-1.00 | 0.40-0.80 | 0.08-0.10 | NI |

0.60-1.00 | ||||||

EN-353 | 0.10-0.20 | 0.35 | 0.50-1.00 | 0.75-1.25 | 0.08-o.15 | NI |

1.00-1.50 |

Mechanical Properties

Grade | Hardening Temperature | Quenching Medium | Tempering Temperature | Brinell Hardness | JapanHe | AISI |

EN-1A | - | - | - | - | - | - |

EN-8 | 750-900 | OIL | 150-200 |

| - | 1040 |

EN-9 | 850-900 | OIL | 200-250 | 55-60 | - | - |

EN-19 (V 320) | 900-950 | OIL | 200-225 | 45-55 | SCM 4 | 4140 |

EN-24 (V 130) | 830-860 | OIL | 540-680 | 45-55 | SNCM 8 | 4340 |

EN-31 R-100 | 820-860 | OIL | 180-225 | 59-65 | - | - |

EN-36C | 780-860 | OIL | 170-210 | 61-63 | SNC 22 | 3415 |

EN-42 | 600-700 | DIRECT HARDENING |

| 40-45 | - | - |

EN-44 | 650-750 | OIL | 150 | 45-50 | - | - |

EN-45 | 830-860 | OIL | 470-520 | 50-55 | - | 9255 |

EN-351 | 850-860 | OIL | 175-200 | 62-64 | - | - |

EN-353 | 840-870 | OIL | 150-200 | 62-64 | - | - |

Scope of Application

The EN series is widely used in many general engineering applications. Typical applications include shafts, studs, bolts, connecting rods, screws, etc.

Carbon steel rod inventory

Product delivery

Product delivery

Visit and Inspect

Participate In Exhibition