LSAW Pipe Longitudinal Submerged Arc Welding

- China

- 15-25 Working Days

- Factory Direct Supply

LSAW Pipe Longitudinal Submerged Arc Welding

The longitudinal submerged arc welded pipe is made of steel plate as raw material, which is formed by a forming machine, and then double-sided submerged arc welding is carried out. Through this process, the LSAW pipe will have excellent ductility, toughness, uniformity, plasticity and good sealing performance.

LSAW Pipe Description

The longitudinal submerged arc welded pipe is a high-quality, efficient and reliable welded steel pipe with many advantages and a wide range of applications. It can not only meet the needs of different fields, but also has good anti-corrosion properties, extending the service life of steel pipes. At the same time, this kind of steel pipe also has good wear resistance and impact resistance, and can be used in various complex environments. Therefore, it is widely used in petroleum, chemical industry, natural gas, water supply and drainage and other fields. In addition, this pipe has a wide range of pipe diameters and wall thicknesses, which can meet the needs of different fields.

Product Parameters

Product Name | LSAW pipe |

Standard | EN/DIN/JIS/ASTM/BS/ASME/AISI etc. |

Outer Diameter | 406mm-4500mm |

Wall Thickness | 8-100mm |

Length | 5.8 meters-12.5 meters, Support customization |

Manufacturing Type | Longitudinal submerged arc welded pipe and welded steel pipe |

Product Material

Standard | Material |

ASTM A53 | A53GR.B |

ASTM A252 | A252 GR.2, ASTM A252 GR.3 |

GB/T3091 | Q195, Q235B, Q345A, Q345B |

API 5L | Gr.B, X42, X46, X52, X56, X60, X65, X70, X80 |

GB/T9711-2011 | L210, L245, L290, L320, L360, L390, L415, L450, L485 |

EN 10219 | S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

A671/A672 CL10-CL13 | CA55, B65, B70, C70 |

Chemical Composition & Mechanical Properties

Standard | Grade | Chemical Composition (max) % | Mechanical Properties (min) | |||||

C | Mn | Si | S | P | Yield Strength (Mpa) | Tensile Strength (Mpa) | ||

GB/T 700-2006 | A | 0.22 | 1.4 | 0.35 | 0.050 | 0.045 | 235 | 370 |

B | 0.2 | 1.4 | 0.35 | 0.045 | 0.045 | 235 | 370 | |

C | 0.17 | 1.4 | 0.35 | 0.040 | 0.040 | 235 | 370 | |

D | 0.17 | 1.4 | 0.35 | 0.035 | 0.035 | 235 | 370 | |

GB/T 1591-2009 | A | 0.2 | 1.7 | 0.5 | 0.035 | 0.035 | 345 | 470 |

B | 0.2 | 1.7 | 0.5 | 0.030 | 0.030 | 345 | 470 | |

C | 0.2 | 1.7 | 0.5 | 0.030 | 0.030 | 345 | 470 | |

BS En10025 | S235JR | 0.17 | 1.4 | - | 0.035 | 0.035 | 235 | 360 |

S275JR | 0.21 | 1.5 | - | 0.035 | 0.035 | 275 | 410 | |

S355JR | 0.24 | 1.6 | - | 0.035 | 0.035 | 355 | 470 | |

DIN 17100 | ST37-2 | 0.2 | - | - | 0.050 | 0.050 | 225 | 340 |

ST44-2 | 0.21 | - | - | 0.050 | 0.050 | 265 | 410 | |

ST52-3 | 0.2 | 1.6 | 0.55 | 0.040 | 0.040 | 345 | 490 | |

JIS G3101 | SS400 | - | - | - | 0.050 | 0.050 | 235 | 400 |

SS490 | - | - | - | 0.050 | 0.050 | 275 | 490 | |

API 5L PSL 1 | A | 0.22 | 0.9 | - | 0.03 | 0.03 | 210 | 335 |

B | 0.26 | 1.2 | - | 0.03 | 0.03 | 245 | 415 | |

X42 | 0.26 | 1.3 | - | 0.03 | 0.03 | 290 | 415 | |

X46 | 0.26 | 1.4 | - | 0.03 | 0.03 | 320 | 435 | |

X52 | 0.26 | 1.4 | - | 0.03 | 0.03 | 360 | 460 | |

X56 | 0.26 | 1.1 | - | 0.03 | 0.03 | 390 | 490 | |

X60 | 0.26 | 1.4 | - | 0.03 | 0.03 | 415 | 520 | |

X65 | 0.26 | 1.45 | - | 0.03 | 0.03 | 450 | 535 | |

X70 | 0.26 | 1.65 | - | 0.03 | 0.03 | 585 | 570 | |

Scope of Application

Longitudinal submerged arc welding pipe products are suitable for all kinds of oil and natural gas transmission pipelines and construction steel structures, such as oil pipelines, natural gas, urban pipeline networks, mining coal water slurry pipelines, high-voltage transmission lines, wind power generation, bridges, high-speed railways, etc.

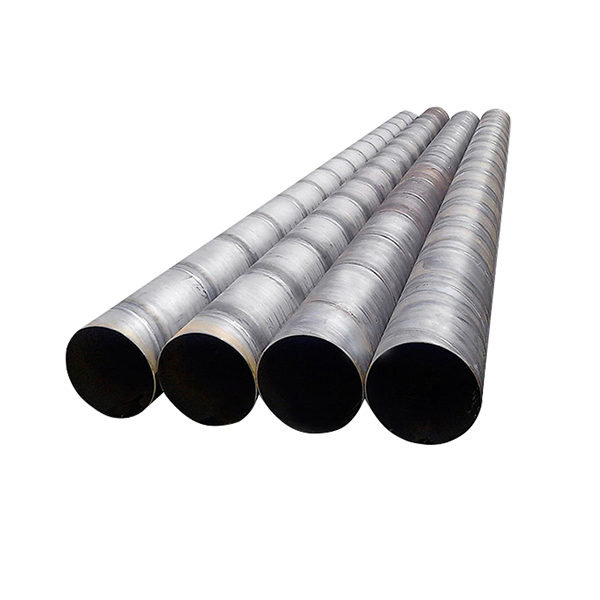

Product Show

Cooperative Client

Packing And Shipping

Participate In Exhibition